Bar Grating

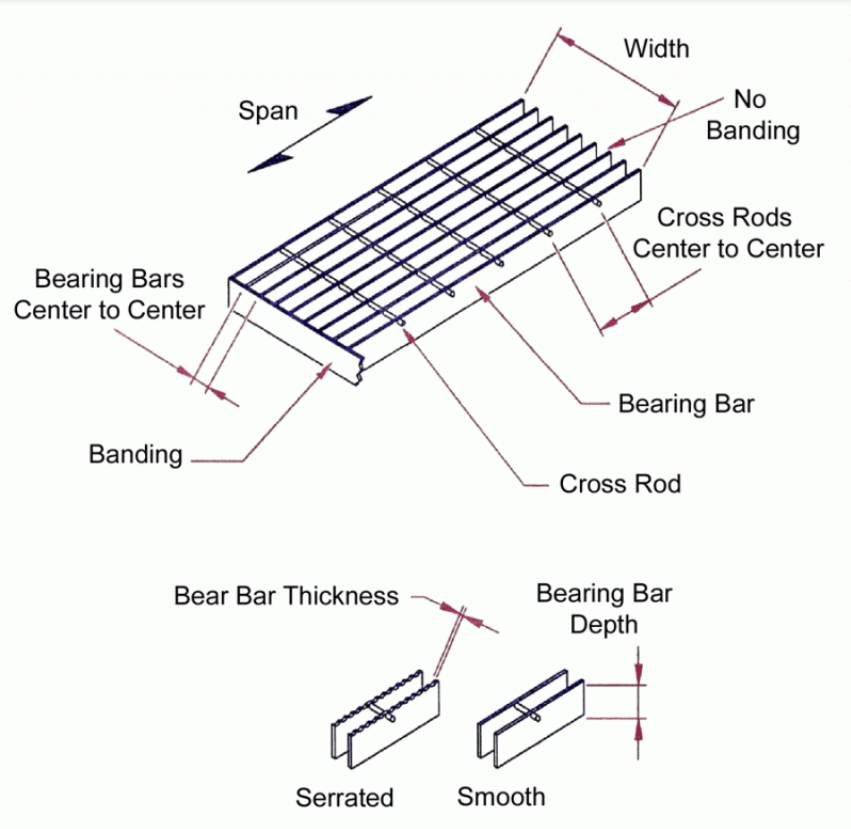

Our industrial metal gratings are available as stock panels or are custom fabricated to your size and specifications. This includes options available in stair treads. Stair treads can be custom fabricated to your needs with both smooth or serrated surfaces, and a variety of non-slip nosing options.

Offered as bar gratings, & plank gratings/planks, we have a choice of standard spacing for normal pedestrian traffic or close mesh for high heels or ADA compliance.

Material options include plain steel, galvanized steel, aluminum, or stainless steel. Our fiberglass reinforced plastic (FRP) industrial grating options are pultruded, I-bar, or molded.

We have many types of gratings available:

- Welded Steel and Pressure-Locked: Permanent locking solutions that can withstand extreme pressure. Cross bars remain in a fixed position for a uniform appearance. Our products are ideal for industrial or architectural installations as light and air are allowed to pass through.

- Swage-Locked: A type of grating useful for industrial applications involving liquids. Swage-locked grating consists of cross bars lined through preexisting holes in a metal material. Aluminum swage-locked grating is a popular choice for industrial walkways and platforms.

- Riveted: An industrial form of grating featuring a series of crimp bars. Riveted grating products allow users to create durable joints when fastening metal surfaces together.

- Reticuline: Industrial grating products with rounded metal connections. Reticuline grating is excellent for stair treads and platforms where slipping is a concern.

- I-Bar: A lightweight metal grating configuration that offers exceptional strength. Straight weight-bearing bars leave room to draw up walkways, platforms, and stairs based on the dimensions of your facility.

- Extruded Plank: Industrial grating products with intricate vents. Extruded plank grating is perfect for catwalks and industrial walkways, as designs are engineered for maximum traction. Allow air, light, and heat to pass through metal without compromising safety initiatives in your plant or facility.

- X-Bar Press-Locked: Metal products that have cross bars connecting at a slight angle. Here, manufacturing procedures result in surfaces that have “X” shape designs throughout.

Bar grating thicknesses measure .75″ to 6″ high. Finishes offered are mill finish, painted, powder coated, or galvanized with either smooth top or a serrated top. Grating can have either untrimmed ends (open fingers), or trim banded (closed ends).

Grating can be provided to comply with the Americans with Disabilities Act if requested. All of our gratings are load tested to ensure strength and safety. On large fabricated jobs, we will prepare drawings for your approval and erection.